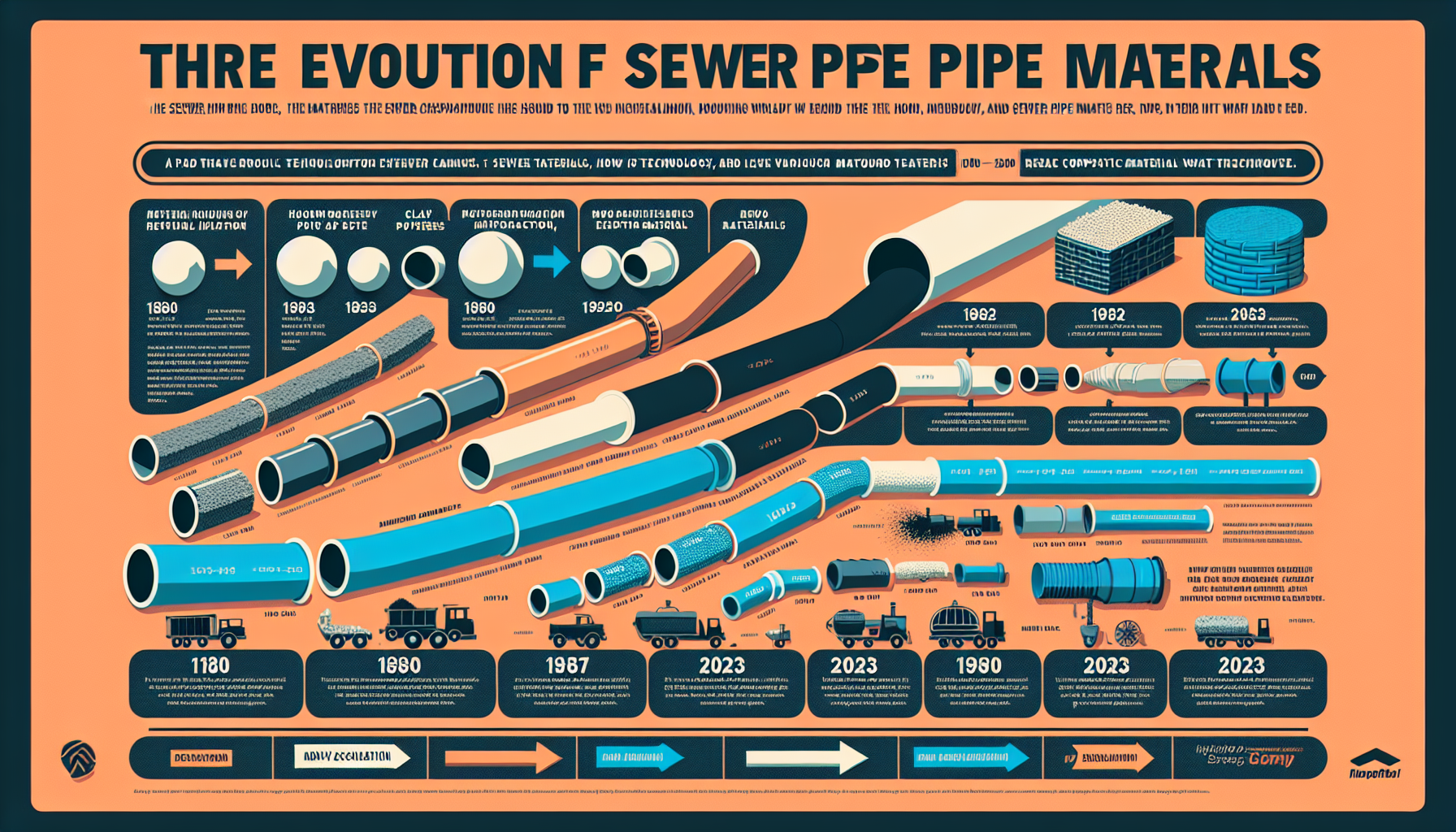

[SUBHEADING]The Dawn of Modern Sewer Systems: The 1800s[/SUBHEADING]

The history of sewer systems is as old as the rise of human civilization, but the evolution of sewer pipe materials began taking significant strides in the 1800s. At the start of this century, the primary material used in the construction of sewer pipes was clay. Renowned for its natural availability and fairly straightforward manufacturing process, clay pipes became a popular choice. These pipes, initially made by hand before the advent of industrial machinery, were susceptible to breakage and infiltration. Nevertheless, clay pipes laid the groundwork for the increasingly sophisticated sewage systems that would develop over the centuries.

[SUBHEADING]The Impact of Industrialization: Cast Iron Pipes[/SUBHEADING]

As the world moved forward into the age of industrialization, materials and manufacturing processes improved. Cast iron pipes emerged onto the scene thanks to their enhanced durability and strength, reducing the occurrence of breakages that plagued their clay predecessors. The ability to withstand high pressures and transport water efficiently brought cast iron pipes to the forefront in urban sewer construction through the late 1800s and early 1900s. The greater engineering capability coupled with booming urban growth ensured that cast iron had a significant role in expanding the reach of organized waste management.

[SUBHEADING]Pushing Forward: Concrete and Orangeburg Pipes[/SUBHEADING]

The early to mid-twentieth century saw further diversification in sewer pipe materials. Reinforced concrete became a favored material for larger sewer pipes, praised for its longevity and resistance to corrosion. Ideal for heavy loads and large-scale sewage systems, concrete pipes significantly contributed to the advancement of municipal infrastructure. Alternatively, on a smaller scale, Orangeburg pipes (also known as “fiber conduit” pipes) were constructed with layers of wood pulp and pitch. They were lightweight and easy to cut but fell out of favor by the 1970s due to their relatively short lifespan and susceptibility to deformation.

[SUBHEADING]Innovation in the Late Twentieth Century: PVC and Other Plastics[/SUBHEADING]

Polyvinyl Chloride (PVC) pipes revolutionized the industry in the latter half of the twentieth century, offering superior corrosion resistance, ease of installation, and long-term cost-effectiveness. Alongside PVC, other plastics like High-Density Polyethylene (HDPE) also gained traction. These materials proved to be resilient against chemical attacks and displayed exceptional flexibility, making them suitable for various ground conditions and installation methods. Their light weight and ease of transport further contributed to their widespread adoption in sewer systems around the world.

[SUBHEADING]Entering the Twenty-First Century: Trenchless Technology and Composite Piping[/SUBHEADING]

As Kalin Excavation in Spokane, WA, can attest, the evolution of sewer pipes has entered a dynamic era with the development of trenchless technologies. These innovative approaches to pipe installation and repair, such as Cured-in-Place Pipe (CIPP) lining and pipe bursting, have reduced the need for extensive excavation, minimizing disruption and decreasing costs. Composite materials have become the crux of this technology, offering a seamless way to rehabilitate aging infrastructure without the need for complete replacement. Composites, materials made from two or more constituent materials with different physical or chemical properties, offer unrivaled strength-to-weight ratios and longevity.

[SUBHEADING]Looking to the Future: Smart Pipes and Sustainability[/SUBHEADING]

The period from the late twentieth century to 2023 has been marked by an increasing emphasis on sustainability and resilience. Smart pipes, embedded with sensors to monitor flow, pressure, and structural integrity, represent the cutting edge of sewer infrastructure. They allow for real-time data analysis and proactive maintenance, significantly increasing the efficiency of sewage systems. Moreover, materials engineers and technologists are continuously looking for more sustainable and environmentally friendly alternatives that will define the next generation of sewer pipes.

Kalin Excavation in Spokane, WA, has borne witness to the transformation of sewer pipe materials from simple clay to advanced composites and smart pipe systems. They understand the importance of keeping pace with technological advancements to ensure the resilience and effectiveness of sewer infrastructure. Looking ahead, the integration of advanced materials, smart technology, and a focus on sustainability are set to shape the future of this critical aspect of urban planning and public health.